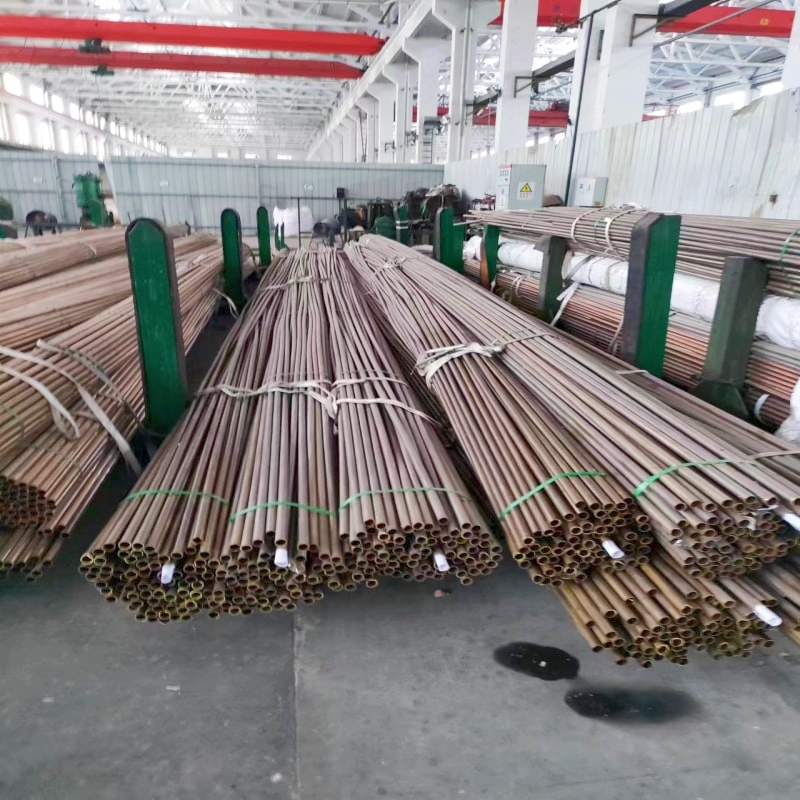

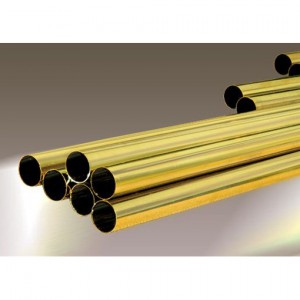

Copper Tubes

| Product Name | Copper,Brass,Copper Alloy Pipe&Tube for the Oil refinery,Petrochemical,LNG,Ship-building,Power plant and Desalination plant |

| Shape | Straight Tube/Coil Tube |

| Size | Customized |

| Grade | Pure Copper: C10100 / C10200 / C11000 / C12000 / C12200 Copper Alloy: C14500 / C17200 / C17300 / C17510 / C18150 / C19200 / C19210 / C19400 Brass: C22000/C23000/C24000/26000/26800/27000 Lead Brass: C33000 / CuZn36Pb3 / C35000 / C35300 / C36010 / C37000 / 37700 / C38000 / C38500 / CuZn39Pb3 / CuZn40Pb2 Tin Brass: C44300 / C44500 / C46400 / HSn90-1 Aluminum Brass: C68700 / HAl77-2 / HAl66-6-3-2 / HAl64-3-1 Tin Bronze: C51000 / C51100 / C51900 / C52100 / 54400 / CuSn4 / CuSn5 / CuSn5Pb1 / CuSn6 / CuSn8 Aluminum Bronze: C60800 / C61300 / C61900 / C62300 / C63000 Copper Nickel Alloy: C70400 / C71500 / C70600 / C70620 / C73500 / 75200 / 76200 / C77000 |

| Standard | ASTM B280 / B111 / B152 / B88 / B49 / B359 / B505 |

| Temper | H,1 / 2H,3 / 4H,1 / 4H,EH,SH,O60 and etc. |

| Surface | Mill,Polished,bright or customized. |

| MOQ | 1Piece |

| Delivery Time | 7-10 days after the payment received |

Copper tubes are important in the plumbing and HVAC industries. Both retrofitted and new industrial, commercial, and residential installations require copper tubes as paths for refrigerants to flow between components. Copper tubing is available in hard-drawn and soft tempers and a range of wall thicknesses and diameters. Standard fittings are designed to fit most system applications, and joints are reliable and cost-effective to produce. Sizing, fittings, and installation layout must be precisely specified for the system to run efficiently.

Another key function of copper tubing is to protect the refrigerant from environmental exposure and, therefore, from absorbing heat from the atmosphere. The copper tube should be insulated between the compressor and the evaporator on the low-pressure side of the system. This is why insulation material wrapping is often seen around copper tubing. Wrapping also prevents condensation on the tubes.