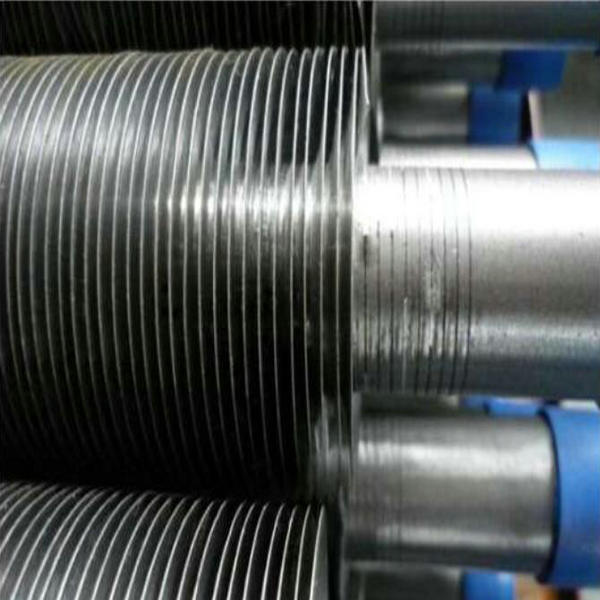

Excellent quality Spiral Wound Finned Tubes - G Type Embedded Spiral Finned Tube – Datang

Excellent quality Spiral Wound Finned Tubes - G Type Embedded Spiral Finned Tube – Datang Detail:

● Bare tube general material: Copper, Alloy, Carbon Steel, Stainless Steel

● Bare tube OD: 16-63mm

● Fin general material: Aluminum

● Fin pitch: 2.1-5.0mm

● Fin height: <17mm

● Fin thickness: ~0.4mm

G type embedded spiral finned tube is processed from a certain width in the steel pipe and spiral groove depth, then inlays the ribbon on the steel pipe by the equipment. In winding process, as the pre-tightening force to a certain extent so the strip will be firmly in the spiral groove, to ensure there is a certain contact area between steel band and steel pipe. In order to prevent the strip spring falling off the light tube, the two ends of the steel strip need to weld onto the steel pipe. In order to set easily, there should be a certain clearance between steel belt and spiral groove. If the clearance is too small the setting process will be difficult to proceed smoothly. In addition, the steel belt of winding there will always be a certain amount of rebound, which makes it cannot very good joint among the steel belt and spiral groove bottom. Inlaid fins can be conducted on general equipment, and they cost little. Mcelroy companies in the United States the company I used the advanced production equipment, slotting embedding technology is advanced, from stable, embedded and firm, pulled off force not less than 70 n, the allowable temperature can reach 400 ℃, has the strong ability of temperature resistance and thermal shock, widely used in petrochemical air cooler.

Product detail pictures:

Related Product Guide:

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for Excellent quality Spiral Wound Finned Tubes - G Type Embedded Spiral Finned Tube – Datang , The product will supply to all over the world, such as: New Zealand, Korea, Germany, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.