Products

-

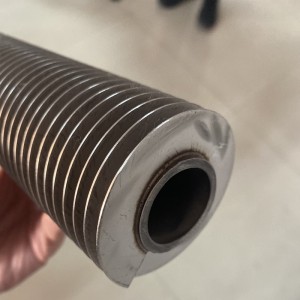

ASTM A179 Embedded Finned Tube Steel Heat exchanger & Boiler Tube

ASTM A179 covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular, heat exchanger, condensers, and other heat transfer services. seamless ASTM A 179 steel tube is supplied and produced by cold drawning method. Chemical composition contains carbon, manganese, phosphorus, and sulfur.

-

A213 T22 Finned Pipe Heat Exchanger Fin Tube Solid Type Cold Drawn

Tube Type:Seamless (Cold Drawn)

Ends:Plain ends or bevel ends.

Surface protection:black painting,anti-rust oil or varnish. -

63/37 Brass Tubes

Detail General extrusion production capacity General specifications of Extruded Fin Tubes Extrusion Facility: 30 finning machines. Daily capacity up to 50000 meters. Extruded fins type: solid plain and serrated. Tube OD: 12mm min.~50.8mm(2”) max. Tube Length: 18 meters max. Fin Height: 16.5 mm max. Fin Thickness: appr. 0.4mm/0.5mm/0.6mm Fin Pitch: 1.5mm min. Specifications Extruded Bimetallic Finned Tube is combined with two different materials. Items General Mater... -

70/30 Brass Tubes

Product Description Datang manufacture, exports and supplies wide range of 70/30 Brass Tubes used in varied areas. A copper zinc alloy containing tin and small amount of arsenic. This is added as an inhibitor against dezincification. The alloy exhibits a good combinations of strength and ductility and is commonly selected whenever excellent cold working properties and relatively low cost are desirable. 70/30 Brass Tubes are mainly used in Sugar Industries, Ammunition and General Enginee... -

70/30 Cupronickel Tubes

Product Description Datang manufacture, exports and supplies 70/30 Cupro Nickel Tubes which is a 70% copper 30% nickel alloy, offering improved levels of corrosion resistance in marine and salt water environments. 70/30 Cupro Nickel Tube widely used for Heat Exchangers, High Capacity Power Plants, Ship Building & Ship Repairs, Condensers, Offshore Oil rigs, Distiller Tubes, Evaporators. Technical Specification of 70/30 Cupronickel Tubes : -

90/10 Cupronickel Tubes

Product Description Datang manufacture, exports and supplies 90/10 Cupro Nickel Tube which have excellent resistance to corrosion in sea water. Besides this, these tubes have high resistance to corrosion and air impingement. Cupro Nickel Tubes have good strength and ductility at ordinary temperatures and relatively high strength at elevated temperatures. 90/10 Cupro Nickel Tubes which are widely used in condensers, coolers, Power Plants, Ship Building & Ship Repairs, and heat exchang... -

Extruded Fin Tube

Datang produces Extruded Fin Tubes which are manufactured by cold rotary extrusion process. The Extruded Fin is formed from an outer aluminium tube with a large wall thickness, which is aligned over an inner base tube. The two tubes are pushed through three arbors with rotating discs that literally squeeze or extrude the aluminium fins up and out of the muff material in a spiral shape in one operation. The process of extrusion hardens the fins and prevents dissimilar metal contacts at the fin root. The exposed external surface is aluminium and there are no minute gaps between adjacent fins where moisture can penetrate. This ensures good efficiency that is expected when using an extended surface for heat transfer. During the finning process a tight mechanical bond is made between the finned aluminium outer tube and inner base tube of the required metal.

-

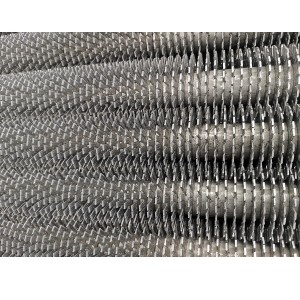

G Type Embedded Spiral Finned Tube

The fin strip is wound into a machined groove and securely locked intd place by back filling with base tube material. This ensures that maximum heat transfer is maintained at high tube metal temperatures.

-

High Frequency Welded Fin Tube for Air Dry

High frequency welding spiral fin tube is a new kind of heat transfer material which has the feature of wearing resistance and high efficient. And it is a kind of high efficiency and energy saving heat transfer element.

-

T-Type High Efficient Heat Exchange Finned Tube

T fin tube is a kind of high efficient heat exchange tube that is made by rolling processing and molding of the light pipe. Its structure characteristic is forming a series of spiral ring T tunnel on the outside the pipe surface.

-

HFW sprial SERRATED fin tubes apply in HEAT RECOVERY STEAM GENERATOR

● Bare tube general material: Carbon Steel, Copper, Stainless Steel, Alloy ● Bare tube OD: 10-38mm ● Fin pitch: 0.6-2mm ● Fin height: <1.6mm ● Fin thickness: ~0.3mm T fin tube is a kind of high efficient heat exchange tube that is made by rolling processing and molding of the light pipe. Its structure characteristic is forming a series of spiral ring T tunnel on the outside the pipe surface. The medium outside the pipe forms a series of bubbles in the tunnel nuclear when heated. And becaus... -

Copper Finned Tubes,Pure Copper Composite Finned Tube

● Bare tube general material: Carbon Steel, Copper, Stainless Steel, Alloy ● Bare tube OD: 10-38mm ● Fin pitch: 0.6-2mm ● Fin height: <1.6mm ● Fin thickness: ~0.3mm T fin tube is a kind of high efficient heat exchange tube that is made by rolling processing and molding of the light pipe. Its structure characteristic is forming a series of spiral ring T tunnel on the outside the pipe surface. The medium outside the pipe forms a series of bubbles in the tunnel nuclear when heated. And becaus... -

Extruded Fin (Bi-metallic Fin)

High-efficiency Extruded Finned Tube for higher temperature applications giving complete and permanent atmospheric corrosion protection of the base tube. Using over 40% more aluminium than the equivalent applied fin, the extended fin is very robust and resistant to mechanical damage, allowing the Extruded Finned Tube to be cleaned without damage using either steam or high-pressure water Extruded Finned Tube is composite with iron-aluminum or copper-aluminum tube rolling out the fin, which fe... -

Extruded Bimetallic Finned Tubes

High-efficiency Extruded Finned Tube for higher temperature applications giving complete and permanent atmospheric corrosion protection of the base tube. Using over 40% more aluminium than the equivalent applied fin, the extended fin is very robust and resistant to mechanical damage, allowing the Extruded Finned Tube to be cleaned without damage using either steam or high-pressure water Extruded Finned Tube is composite with iron-aluminum or copper-aluminum tube rolling out the fin, which fea... -

Laser welded carbon steel finned tube

High-efficiency Extruded Finned Tube for higher temperature applications giving complete and permanent atmospheric corrosion protection of the base tube. Using over 40% more aluminium than the equivalent applied fin, the extended fin is very robust and resistant to mechanical damage, allowing the Extruded Finned Tube to be cleaned without damage using either steam or high-pressure water Extruded Finned Tube is composite with iron-aluminum or copper-aluminum tube rolling out the fin, which fea...